David Surplus, one of the directors of B9 Energy, discusses compressed air storage systems at site visit in May 2016 to Guardbridge Energy Centre, St Andrews University, which is central to the university’s strategic drive to become the UK’s first energy carbon neutral university.

Case study 4

This demonstration will illustrate the benefits and opportunities of providing electrical storage through compressed air and stored heat to areas of relatively weak existing electrical infrastructure. The location is in Lecale, a semi-rural area in the south-east of Northern Ireland.

The unit will help to demonstrate the ability to store and re-generate electricity with standardised technology components and will validate models for operating the unit within a residential setting both to maximise the penetration of local sources of renewable energy and to minimise transmission and distribution network reinforcement requirements. It is also intended that the unit will demonstrate applications for compressed air storage within relevant markets including system support services, capacity provision and load-on-demand services.

Demonstration of storage in a residential district (via a small sized Compressed Air Energy Storage)

This demonstration, a first of its kind system, will illustrate the benefits and opportunities of providing electrical storage through the media of compressed air and stored heat to areas of relatively weak existing electrical infrastructure.

Lecale, Northern Ireland

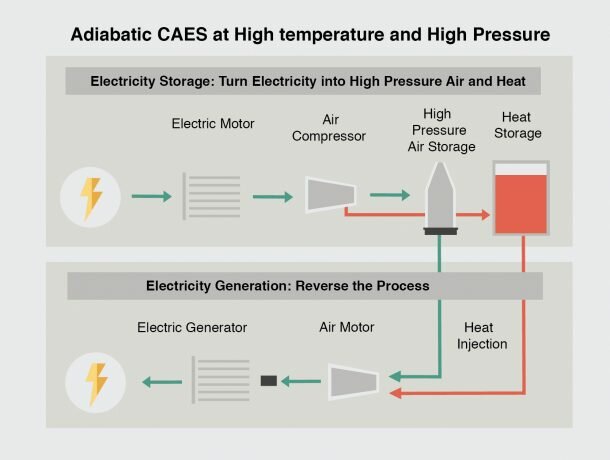

The demonstration unit will take electricity from the grid to drive a compressor for storing compressed air in air storage cylinders. It is the first time such as system is tested outside of a lab environment. The heat released in this process will be recovered and stored in molten salt tanks. When electricity is required for export, the compressed air is directed through an expander with heat injection from the heat store to drive a generator. There will be a site control room to monitor and control the processes and to facilitate close monitoring of the operation of the system.

So far Compressed Air Energy Storage is usually regarded as a form of large-scale energy storage, comparable to a pumped hydropower plant. Such a CAES plant compresses air and stores it in an underground cavern, recovering the energy by expanding (or decompressing) the air through a turbine, which runs a generator. Unfortunately, large-scale CAES plants are very energy inefficient. The low efficiency is mainly since air heats up during compression.

The main reason to investigate decentralised compressed air energy storage is the simple fact that such a system could be installed anywhere, just like chemical batteries. The area occupied by the demonstration unit will be reasonably compact, totalling about 20m by 20m excluding space for access and parking.

Responsable partner: B9 Energy Storage Ltd.b

“Driving innovation in distributed compressed air energy storage with integrated heat recuperation“

David Surplus, B9 Energy Storage Ltd.

site visit in May 2016

Bishopscourt Central substation 2

Marine Current Turbines. The local SeaGen tidal device.

SeaGen, the world’s first commercial-scale tidal stream energy system, is one of the local technologies whose output supplies the 33kV substation that the energy storage demonstration unit will be serving.

Typical layout of compressed air energy storage system using high temperature air and heat

The compressed air unit comprises: air, hot water and molten salt storage tanks; compressors and expanders for converting the electricity into the storage media and reversing the process to generate electricity; heat exchangers and control facilities.

Compressed air energy storage with high temperature air and water

When generation capacity on the local network is greater than is required for local demand, the unit commences to compress air, storing the compressed air in tanks and the resulting heat in molten salt. When the electricity is needed, the compressed air is expanded and the stored heat is injected to maintain the overall efficiency of the process.