1 converter Studer XTM 6000-48 with a discharge capacity of 5kW and a charge capacity of 4,8kW, to connect on phase 1

2 converters Studer XTM 4000-48 with a discharge capacity of each 3,5kW and an charge capacity of 24kW, to connect to phases 2 and 3

24 Rolls batteries with a total capacity of 101kWh, or 60,7kWh net capacity (60% depth of discharge)

Online dashboard that allows the tracking of status and history from the consumption of the batteries

Controle software for the following functionalities:

Automatic charge outside working hours in function of the ORC production

Automatic discharge during working hours in function of the electricity consumption of the office

uninterruptible power supply

Case study 6

Beneens is situated in a small industrial site. We heat our office, workshop and painting room with waste wood.

As our company needed to invest in new office space we also needed to invest in a new wood fired boiler. Our old boiler had a number of technical problems.

During the research for a new wood fired boiler, in collaboration with VITO, the idea came to provide the new SME-zone with heath delivered by a district heating network.

Demonstration of multi energy grid in industrial area

Beneens demonstration in the STORY project are efficiency enhancement and active control of ORC through the use of thermal storage.

Olen, Belgium

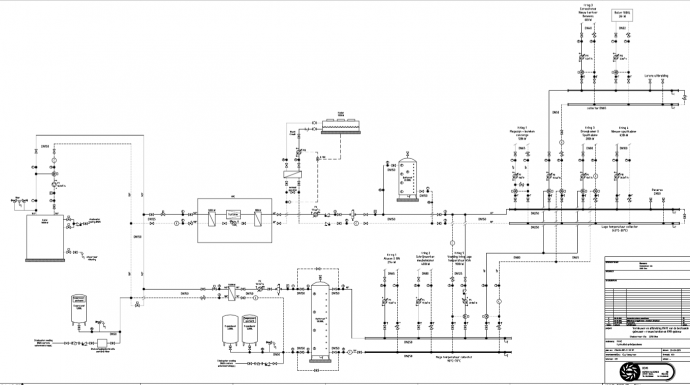

At our demonstration site we will build a new wood fired boiler (1.6 MW) with a heath delivery of 150°C. This boiler is in connection with a ORC (Organic Rankine Cycle). The ORC produces electricity of +/- 90 kWe/h.

In order to increase flexibility of the system thermal energy storage based on a hot water storage tanks are added. To provide sufficient wood waste for the ORC in winter and summer there is an option to collect waste wood from other companies.

The innovative aspects of the Beneens demo in the Story project are:

- Efficiency enhancement and active control of ORC through the use of thermal storage

- State of charge estimation of thermal energy storage with limited sensors

- Potential optimization of the thermal grid through double use in intervals

the use of local batteries to reduce congestion and peak demand on the private grid (if economically feasible)

Responsible partner: Beneens & Vito

„STORY for us is a small SME thinking big ….“

Joeri Beneens, Beneens

Installed batteries

Picture of the installation with on the right-hand side the silo for sawdust, the breaking installation for waste wood and the storage of waste wood. The dry cooler for the ORC installation is on top of the building.

This picture shows the (red) wood fired boiler at the right, the 50.000l thermal storage tank at the left, and part of the heat network switching system centrally.

The waste wood boiler

The waste wood boiler with a thermal capacity of 1,600 kW provides heat at a temperature of 145°C to an Organic Rankine Cycle (ORC) and the high temperature heat collector (90°C) via a heat exchanger. High temperature heat consumers like the buildings of Alucon, BM, Beneens Constructions and the spraying and drying rooms are connected to the high temperature collector. In order to increase the efficiency of the boiler a thermal energy storage system is installed in between the heat production and the high temperature heat consumers.

The ORC converts high temperature heat from the waste wood boiler into electricity (90 kWe) and low temperature heat (910 kW). The low temperature heat is used for the existing and new office buildings of Beneens, the spraying rooms and in the SME district that has to be developed. In order to increase the efficiency of the ORC a thermal energy storage system is installed in between the ORC and the low temperature heat consumers.

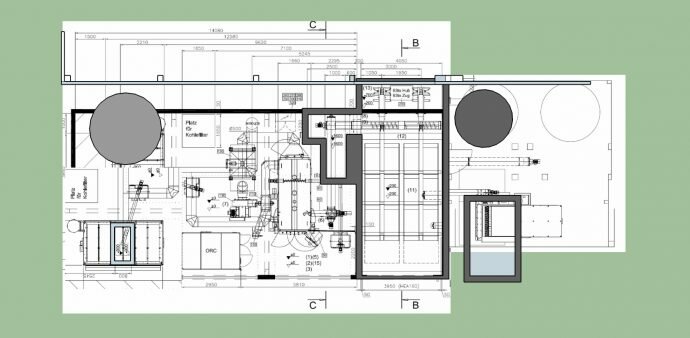

3D simulation of technical building

Technical drawing

Silo for sawdust

Breaking installation for waste wood

Storage of waste wood

Movable floor for waste wood transport

Supply of waste wood to the boiler

Waste wood boiler

Flue gas cleaning installation – cyclonic separation

Flue gas cleaning installation – filter

ORC installation

Thermal energy storage tank (50 m³ – 80°C)

Dry cooler for the ORC installation

Chimney

Technical plan of the new building

left side: water boiler and filter

center: ORC and wood fiber boiler

right side: walking floor and wood crusher

BWood2Energy

Construction company Beneens is an interior and construction company located in Olen (Belgium) and a trendsetter in innovation and sustainability in the build environment. At 14-16 October of 2016 the company celebrated his 80st anniversary, the opening of the new nearly energy neutral office building and the inauguration of the new waste wood energy plant. The new office building is constructed in cross laminated timber with certified PEFC-wood. This way of constructing and new building technologies is ideal for low energy buildings. The building will be used as a show case for potential clients. The new energy plant is used to valorise waste wood from the own carpentry and waste wood from local companies. The waste wood is burned in a biomass boiler generating water at a temperature of 145°C. The heat is used for electricity production in an ORC and for process heating in the company. The waste heat of ORC is used for heating of the existing and new office and a number of low temperature processes.